Imagine you have decided to design a new Cable Assembly and many hours have been spent finding the right connectors going into great detail to make sure it does everything you require of it, now you have the task of selecting the appropriate cable.

Sounds easy right? Unlike many connector choices the cable selection is not so easy so why is this? And what are the factors that should be considered?

Unlike generic or copy connectors branded connectors in most cases are designed in as standard. Many people prefer branded connectors as they believe generic connectors will be of an inferior quality.

For cable on the other hand, it is not so easy to say that unbranded cable is inferior as many cables are made to a specific standard. Take for example Tri-Rated Wire. Some of the most wildly used cable is Tri-Rated however, very few people specify a brand. This is because all Tri-Rated wire must be manufactured according to the strict standards specified. In the case of Tri-Rated it is UL, CSA & BS.

This means you can take a reel of Tri Rated wire from any supplier and you can be confident that the wire will be the same regardless of brand. Consider USB connectors they all do the same and very few people think about the brand of connector on the end of the cable.

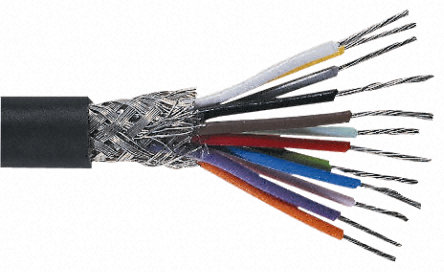

The part of this that becomes tricky is cables where the standards are relatively loose resulting in variations of quality. A good example of this is the very popular Defence Standard (Def-Stan) multicore. Like Tri-Rated Def-Stan cable does have specific standards to follow such as the wire colour codes and other important electrical factors.

However, the Def-Stan is quite loose and open to interpretation. A good example is the braid coverage on a screened cable or the shrink back of conductors when being tinned. Another often overlooked element is the quality of the printing of the colours especially on the bi-colour conductors.

Branded cable on the other hand is usually much more reliable in build quality and a little more cost in the manufacturing process resulting in consistency and better performance.

Of course, Branded can have its down sides also! For example, from time to time manufacturing issues can result in the branded cable being unavailable for some time. A good example of this is a metal panel that was designed to be a perfect fit for one specific branded cable. After some months of build the cable manufacturer (who will remain nameless) was unable to manufacture the cable and the whole project came to a crashing halt as no other cable could be found to have the same physical properties.

Once you start to look into it there are many branded companies that produce wire and cable to international standard but also manufacture to their own.

How do you choose which way to go?

Well here are a few questions to ask yourself which will help direct your decision making process.

Is the cable specification so tight you can only use one cable type?

Are there many cable suppliers for you to obtain stock from?

Is the build quality consistent and if not how much of an issue is this?

How easy would it be to change the cable if you had to?

In conclusion, as someone that works with a lot of branded and generic cable I see the benefits of both each day and I can assure you that some assemblies really benefit from the branded cable specified and others it is noting but problematic because the lead times are always so long.

Of course there are many other factors involved and more than we have time for here today but the important thing to remember is to speak to your cable assembly supplier as they are the ones with expert knowledge who can help navigate through all the available options.

After all it’s what we do!