This week we are discussing Cable Assembly and Harness Testing a subject that is probably one of the most impotent components of any cable assembly.

When purchasing Cables, Harnesses & Looms the customer’s assumption is that all assemblies are tested, and quite rightly so. However, what are the differences in testing and why does it matter?

Most people are familiar with continuity testing which is a basic way of doing point to point testing. In other words, checking that the wires are correctly terminated at each end of the assembly. Continuity testing is great for knowing the assembly has the correct pin out but does not allow for potential wrong connections.

Let’s explore the basic testing options.

Continuity

Point to Point testing where individual wires are tested to make sure each connections are in the right position.

Short Testing

Testing to make sure that no two connections are touching when they should not be. This is when things go BANG if wires short.

Open Connections

Where the connection is either not made or so poorly made that the signal is not strong enough to make a correct connection.

The above covers most basic requirements for the correct testing of Cable Assemblies so what’s the equipment required?

Cable Testers

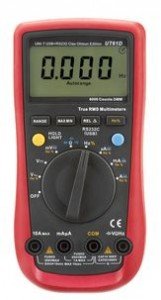

There are three basic testers: Multimetres or buzzers, Basic Testers and Specialist Harness Testers.

Multimetres are very basic and only used for point to point testing, usually by amateurs for basic testing.

Basic Testers are good for testing for opens and shorts and generally give a good visual guide to correct wiring. They are limited, however, by usually being relatively slow to test.

Specialist Cable Testers

These are for the professional Cable and Harness assembler. These testers can be linked to PCs for complex data analysis and storing test results. Tests can be saved into memory and the best part of all enables the very most complex harness to be tested.

Other important differences are the ability to test for the following:

- User-selectable pass/fail resistance thresholds from 0.1 Ω to 500 kΩ.

- Tests resistors, diodes, and capacitors.

- Insulation Resistance

- 4-Wire “Kelvin” Testing capable

There can be a lot more to testing, which we will cover in further blog posts, however, for now this should give you a great idea of what you can do and what the professionals can do. And as always, if in doubt and you need to know your assemblies are fit for purpose, then always consult the experts!