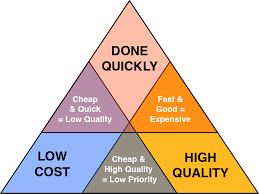

If you are a design engineer, you’re probably under pressure right now to design using lower cost parts. We understand the fear of “low cost” but don’t worry we know the difference between cheap and low cost!

Just like you we spend our time making things, we know what falls apart after 5 minutes and what is good quality and has durability.

Not many people like being cheap and we all want to work with the highest possible quality. In the commercial world this is just not always possible.

The key is understanding the difference between knowing the secrets to working out if a part will be cheap and nasty or acceptable for the application.

Here are some questions that you need to be asking yourself.

Product Lifespan

How long do you expect the product to last? For example, things like Fridges and Washing Machines being domestic appliances must pass stringent test however, the market is extremely competitive so how do they build in quality and keep the costs low, especially when the product is only expected to have a couple of years in service.

The answer is to look at the specification as a starting point. For example, most connectors are built for a specific purpose and you need to be looking at those ranges first. Sometimes simply looking at what electrical properties the connector has can be interesting as some low-cost connectors are in fact quite robust.

Of course, the opposite is also true. Why use connectors with gold plated contacts or fiddly piece parts if you do not need them.

The temptation is to go for copycat connectors of branded ones. Something I do not recommend. We have seen many instances where the copy connectors are inconsistent in quality and there will be very little support if you have a problem. The only deviation would be on connectors such as D connectors, these are fairly universal, and the low-cost ones are generally built well.

Specific Standards

Are you restricted by andy specific safety or electrical standards? If not, then no need to look at connectors or wires with these as it is adding unnecessary costs. Just because a connector may not have any IP ratings, if it is not going anywhere near water then the standards are irrelevant.

Design Aesthetics

If the connector is internal on the device, then why spend any time on what it looks like. As long as it is functional it does not need to be pretty.

There is always a temptation to make things look neat and tidy inside the product but if it’s never meant to be opened then ditch the pride and accept a lower costing connector that does not look so good and may be a better option.

The Labour Element

This is the most often overlooked element of an assembly. How long it takes to assemble. You can spend hours of research looking for the ideal connector but overlook the time it takes to assemble. I have seen this many times where the client expectation was for the assembly to be really low cost because the parts did not cost very much only to find out the assembly time was long.

Sometimes you are in fact better paying more to spend less. In other words, speak to the people that make cables every day they know which connectors are easy to work with.

Some questions to ask about the connectors:

Is it easy to assemble?

Can any of the assembly processes be automated?

Am I worrying too much about how it looks?

How does the manufacturer package the product?

Chances are you have never considered the last one but sometimes connector manufacturers package connectors individually and someone will need to unpack it again adding cost.

Conclusion

Going cheap means not looking at the overall costs but considering the wider elements of the assembly. It is also selecting connectors purely on price and hoping that you can get away with using a connector that is not quite right for the use it was designed for, which is a very dangerous approach.

Low-cost is having a minimalistic approach taking out all the aesthetic and unnecessary specifications leaving you with a simple design that is functional and suitable for the device it is intended for.

I hope this has been helpful and given some guidance and as always it is highly recommended you speak to the cable assembly experts for help and advice.