Types of Flux

For many applications, the flux included in the core of the solder wire is sufficient. However, there are several applications where additional flux is extremely beneficial, such as wire tinning surface mount soldering and de-soldering.

In all cases, the best flux to use is the least acidic (least aggressive) flux that will work on the oxide on the components and result in a good solder bond.

Rosin Flux

Some of the oldest types of flux used is based off pine sap (refined and purified) called rosin. Rosin flux is still used today, but typically is a blend of fluxes to optimize the flux, its performance, and characteristics.

Ideally flux will flow easily, especially when hot, removes oxides quickly, and helps to remove foreign particles from the surface of the metal being soldered.

Rosin flux is the most aggressive flux and in today’s sensitive electronics it is most likely to harm over time if heated to its activity point, meaning it becomes acid and will start to corrode areas where residues have not been removed after use.

Organic Acid Flux

One of the more common fuxes used is water soluble organic acid (OA) flux. Common weak acids are used in organic acid flux, such as citric, lactic, and stearic acid among others. The weak organic acids are combined with solvents like isopropyl alcohol and water.

These are stronger than rosin fluxes and clean the oxides off much quicker. Additionally, the water soluble nature of the organic acid flux allows the PCB to be easily cleaned with regular water.

Cleaning of organic flux is important which is why we use a No-Clean flux where the residue is non conductive and non corrosive.

When using solder with a flux core it is important to match the flux type with the pre tinned flux used on the two parts to be soldered. This will avoid any unnecessary acidic corrosion.

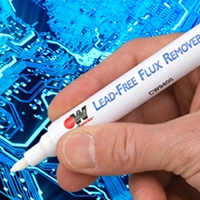

The most important thing to remember is whatever flux you are going to use it is not going to cause any long term problems if you take care to remove any residue, we try even to remove no clean fluxes just to be on the safe side since it’s pretty easy to do with the correct flux removal cleaners.